Product applications

Aluminium composite is a popular sheet material for completing sandwich-panel projects with a superior finish. FALKÔÇÖs insulated wall panels are good carriers for aluminium cladding.

Aluminium composite is a collective name for sheet material. These sheets consist of two aluminium outer skins with a synthetic core, several millimetres thick, in between. The outer aluminium skin is finished with a high-quality coating. The sheets are manufactured by suppliers such as Alucobond or Larson and are custom-made by a specialist company into flat panels, aluminium cassette systems or fascia boards.

Composite materials are popular because of their good fire performance, their light weight, their rigidity and their weather resistance properties. They also offer a high degree of flexibility and versatility when it comes to the design.

Any project where sandwich panels have been used looks sleek and well crafted. But when it comes to taking the finish to a higher level, it is all about the details. In most cases, that higher level is achieved with flashing – fittings made from flat steel sheets used to finish off roof edges, drip flashing, reveals and so on. These flashings are manufactured in our own metal forming shops, often from the same coil of steel from which the sandwich panel is made.

One of the drawbacks of this type of flashing is that it is not inherently rigid and cannot be used to create very large flat areas. For architects aiming for a high-quality finish, aluminium composite is often the material of choice. The advantage of aluminium composite is that it derives its rigidity from its own ‘sandwich effect’ and can therefore span larger areas.

There are endless possibilities for adding the finishing touch to your building with composite. Below is a selection of the most common solutions that are used in projects using our sandwich panels:

Aluminium cassette systems are made from aluminium composite panels ranging in thickness from 4 to 6mm. These are then processed into cassette panels in the processing plant by milling and reshaping the flat panels along the edges.

Hooks are milled along the longer side of the panels. Using pins, these hooks are hooked into aluminium U-shaped profiles that are attached to the sandwich façade.

ÔÇőSecrete-fix aluminium cassette system

Secrete-fix aluminium cassette systems are made of aluminium composite, ranging in thickness from 4 to 8 mm. The cassettes are made by milling flat aluminium composite panels into the required contours. At the top and bottom, the panels are folded into a Z profile, so they can be attached to the rear construction on top of each other.

Vertical or horizontally laid cassette systems are made from aluminium composite panels, ranging in thickness from 4 to 8 mm, and aluminium extrusion profiles, which are incorporated into the cassette panels. This allows them to be stacked and screwed to the rear construction.

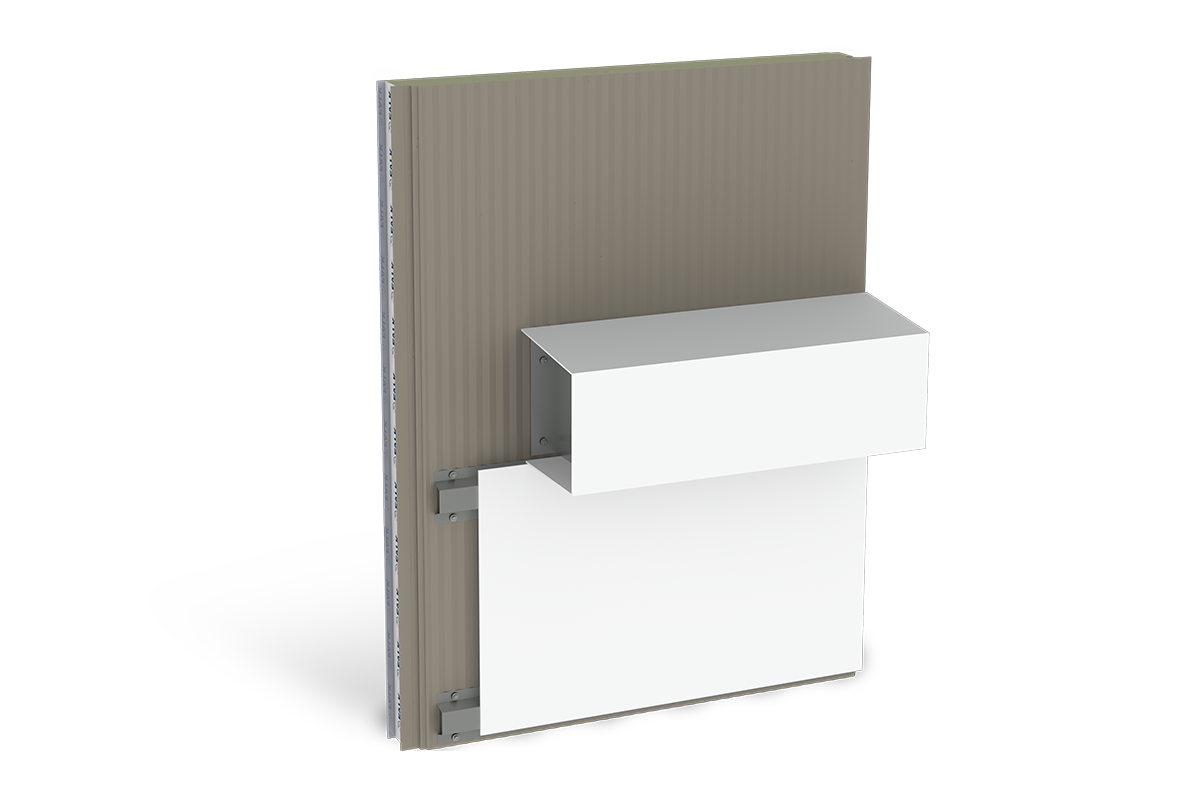

Projecting profiles

Aluminium frames are ideal for creating beautiful accents on your building. Projecting profiles consist of an aluminium cladding or hollow box frame surrounded by a fabricated aluminium composite panel. During production, the cladding or frame is processed into a carrier that meets all the requirements. Where the frames touch, a 0.7mm splice in the same colour or a 4mm layer of composite is applied. This ensures that the seams are finished with precision and prevents visible tension and unevenness in the frames.

Flat panels

The flat panels consist of a 0.5mm coated top sheet, a synthetic fire-resistant core and a 0.5mm uncoated bottom sheet. Aluminium composite is easy to machine into flat panels. With the right detailing, it is possible to achieve a cost-effective and flat façade with with the freedom to design the façade as desired.

Suppliers of aluminium composite

COFAC is one of our regular partners for aluminium composite elements. This company, based in Ede, can manufacture the above systems. They also work with reliable suppliers such as Alucobond and Larson to add a stylish touch to your project.

FALK sandwich panels are often used on buildings where insulation is a key factor. Good insulation contributes to a comfortable indoor climate and, of course, helps to keep energy costs down. The insulation value is determined by the core thickness of the sandwich panels and the airtightness provided by the joining system. The better the insulation, the more comfortable a building will be to live or work in.

For more specialised applications, such as warehouses, cold storage rooms and freezer cells, or for projects in the food industry, there are often specific requirements. In these cases, not only is a good insulation value essential, but so is the coating applied to the interior skin. This is where FALK comes in: we offer a wide range of possibilities for these types of applications.

The exterior skin of a façade panel, on the other hand, is mainly used to enhance the aesthetic value of the building. Choose from the many colours, coatings, profiles and finishes available to create the design you want. Aluminium composite panels are a popular accessory.

FALK insulated panels are available in almost every colour imaginable. In most cases, the exterior skin is finished with a high-quality coating manufactured by Tata Steel (Colorcoat HPS200 Ultra® or Colorcoat Prisma®); the standard finish for the interior skin is FALK Off-White. This is similar to RAL 9002. But you can also select your own colour from the colour library. Discover all our colours on this page. Here you can also request a colour sample!

FALK is the first manufacturer in the world to offer a circular insulated panel. We only have one planet, so we need to use its natural resources wisely. A choice for a FALK insulated roof panel with CradleCore® insulation is a choice for recycling. CradleCore® is a guarantee that we will recycle those panels in the future. This way, raw materials will be available for future generations and you will achieve significant environmental benefits! We have quantified these in an Environmental Product Declaration (EPD). Read all about CradleCore®

Feel free to get in touch if you didn't find all the answers to your questions!

Rene Warring

Sales

My request

Add colour samples and/or product samples now to start your enquiry.

Request colour samplesEnter your name and e-mail address once. Then you will have unlimited access to all FALK downloads, whenever you want!