Sandwich panels

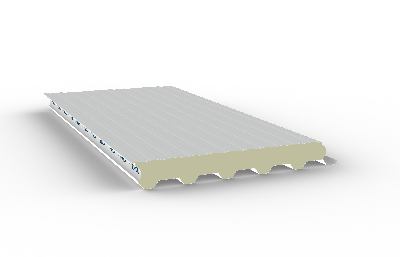

Sandwich panels are prefabricated building elements consisting of two steel sheets with a PIR insulation core in between. FALK sandwich panels for flat roofs are no different: they are self-supporting elements that can be mounted on a flat roof construction.

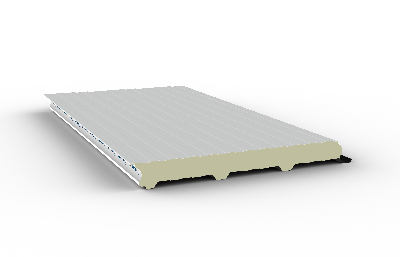

Insulation panels are prefabricated building elements consisting of two steel sheets with a PIR insulation core in between. FALK insulated panels for flat roofs are no different: they are self-supporting elements that can be mounted on a flat roof construction.

Flat roofs are often found on distribution centres, utility buildings and offices. A insulated panel is an ideal solution for this type of application, as it seals the roof in no time with a maximum length of 25 metres, up to 27.5m2 can be sealed in a single crane operation.

Insulation panels are the best choice for cladding a flat roof for a number of reasons:

Flat insulation roof panels have a good insulation value and can help reduce building energy costs by minimising heat loss. Flat insulated roof panels have a maximum RC value of 7.42, which more than meets the requirements of the Dutch Building Regulations.

Flat insulated panels are made from robust materials and can withstand extreme temperatures and weather conditions. FALK flat insulated roof panels are also available with a circular CradleCore® insulation core. This means that FALK flat insulated roof panels are sustainable – both in terms of life cycle and of environmental impact.

Flat insolated roof panels are lightweight and easy to install. Because FALK manufactures the panels to size, they can be installed quickly, saving time and money.

Compared to other roofing materials, insulated panels are relatively inexpensive.

Flat insulated roof panels can be produced in a variety of colours and styles to match the architecture of the building. For example, you can choose a darker coating instead of the standard FALK Off-White interior coating.

The big advantage of using insolation panels for flat roofs is that they are a lot less labour intensive. For example, this roofing method only requires two layers: the panel itself, plus a light-coloured EPDM or PVC membrane on top. This makes the roof completely air and watertight. The insulation and airtightness values exceed the requirements of the Dutch Building Regulations. And the values achieved in airtightness tests are in line with the Passive Building standard.

Bitumen is a type of asphalt that is often used as a roofing material for flat roofs. Although it is inexpensive and easy to install, it is not as durable as some other materials: bitumen can age quickly when exposed to UV radiation or extreme temperatures. Two main types of bitumen are used as roofing materials – black bitumen and APP (Atactic Polypropylene). Black bitumen is usually used as an adhesive layer under roofing materials, while APP is usually used as a roofing membrane.

When used as a roofing material, bitumen is often applied using either hot air or hot glue, which helps to ensure that the material adheres properly to the roof and remains waterproof. However, it is important to ensure that the roof is properly prepared before applying the bitumen layer to ensure that it performs optimally.

It is advisable to seek professional advice before applying bitumen, especially if you have no experience of working on roofs. A mistake when applying the roofing can lead to serious problems in the future.

EPDM (Ethylene Propylene Diene Monomer) is a type of synthetic rubber that is widely used as a finish for flat roofs. It offers several advantages:

EPDM is a popular choice for finishing flat roofs because it is an efficient way to achieve a watertight roof. However, it is important to ensure that the roof is properly prepared before the EPDM membrane is applied and that it is properly secured for optimum performance.

A flat roof can often be a good solution for a new building. This is especially the case if the building is located close to other buildings, as a flat roof takes up less space than a pitched roof.

When renovating an existing building, flat roof panels can be a good option depending on the specific needs of the building. For example, if the current roof is very old or not properly waterproofed, installing a new flat roof may be a good way to solve these problems. It is therefore advisable to seek professional advice before deciding to install a flat roof when renovating a building.

Flat roofs need to be properly insulated in order to prevent too much heat or cold being lost through the roof – which can lead to higher energy costs and uncomfortable temperatures inside the building. Flat insulated roof panels are available in a range of insulation values. For example, our two flat insulated roof panels, FALK 1000 TR and FALK 1100 TR3+, are available in thicknesses ranging from 80mm to 150mm, giving the flat insulated roof panel a maximum RC value of 7.42 m2K/W according to the NTA 8800.

Many of our façade sandwich panels can also be used as roof panels. The FALK 1140 KV PD, FALK 1000 TR PD and FALK 1100 TR3+ PD roof panels are specially designed for flat roofs (a roof pitch between 2 to 4 degrees). The FALK 1000 GL, FALK 1000 TR and FALK 1100 TR3+ are for pitched roofs. You can easily continue these from your façade to your roof, creating a unique design.

Yes! Use our FALKULATOR to calculate the exact span of your project. If you need advice on mounting solar panels on sandwich panels, get in touch! We would be more than happy to talk you through your options.

With a FALK flat roof panel, you can seal and insulate 25m2 of roof in a single crane operation. Simply apply a light-coloured EPDM or PVC membrane and you have a wind and watertight flat roof. A traditional roofing system often consists of four or more layers.

"The standard interior coating for flat roof panels is FALK Off-White. As the panels are manufactured at FALK, you can choose from a wide range of coatings and colours. A popular alternative to FALK Off-White is FALK Reflective White, a reflective traffic white coating that helps save energy. This coating reflects up to 85% of light, so light can be used intelligently in the building: fewer light sources are needed than with a normal coating, which reduces energy costs and cuts down on carbon emissions. Find out more about FALK Reflective White here.

For a more industrial look, you can also go for a darker coating. For example, a FALK Black Matt coating was chosen for this shed. This gives the building a completely different character.

All coatings and colours are therefore available on request. Get in touch to find out about the possibilities!"

Get in touch to discuss your project!

Rene Warring

Sales

Your selected items are (0)

There are currently no downloads here.

Downloads

Coating samples

Don't forget your downloads

Fill in your email address to receive your downloads